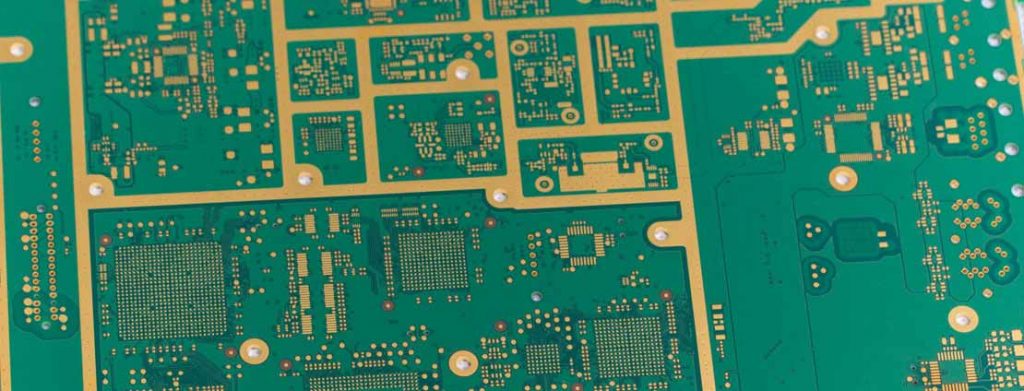

These days it is common knowledge that PCBs are found in every electrical product, large to small (or even tiny), and it is easy to forget that once they were a groundbreaking innovation. Prior to the invention of PCBs any electronic device contained many wires and not only did they get tangled up, took up lots of space but also short circuits were not rare at all. Combine this with the trend of devices getting smaller and smaller, and it is no wonder that a need of a better solution has arisen.

FIRST STEPS

The first PCB concept was invented at the beginning of the 20th century by German inventor Albert Hanson, who filed a patent for a flat conductor for a multi-layer insulating board, but the technology world was not ready to welcome this new electrical component. The stock market crash in 1929 and the Great Depression caused another delay and as a result the PCB was not manufactured and used regularly until 1943 when the US army used it to make proximity fuses during World War II. At the same time Paul Eisler, an Austrian Inventor located in England, took the PCB idea to another level – a copper foil placed on a non-conductive glass base, more similar to the PCB of current days.

SPREAD THE WORD OF PCB

In 1948, after the war, the useful invention was released by USA for commercial use. However, it was only during the 50s the US army developed an auto-assembly process, which led to mass production and brought the PCB to a wider use among electronics consumers. Progress was made in the midst of the cold war as tension ramped up between the opponents – USA and Soviet Union as they both struggled to improve their communications capabilities. A decade later a patent was filed by Hazeltine Corporation for the first plated through-hole technology, which allowed the PCB components to be placed together without crossover connections in a much more reliable way. At the same time surface mount technology was developed by IBM.

BIRTH OF INTEGRATED CIRCUIT

During the 1970s another very important invention came to life – the IC (Integrated circuit). The first microprocessor was actually invented in the late 50s by Jack Kilby, but it took him over a decade to share it with his colleagues at Texas Instruments, which led to the development of the first IC. Following the birth of the IC into the world of electronics manufacturing using a PCB became mandatory.

PCB DESIGN UPGRADE

Up until the 1980s, PCBs were still drawn by hand, which was of course less dynamic and allowed saving and transferring of the designs only with photographs. Then the computers and EDA (Electronic Design Automation) software kicked in, making the PCB designs dynamic and integrated into PCB manufacturing machinery. At the same time compatible and light gadgets, such as the Walkman and cordless phones, were winning the crowd, using small PCBs as their basis.

KEEPING IT LIGHT

During the 1990s the electronic devices continued to shrink, which made manual PCB manufacturing almost impossible, and made the machinery manufactured PCBs in even higher demand. The internet was also born and started a revolution, turning the personal computer into a must-have. Later Cell Phones were introduced, a technological jump which would never have happened without the progress in the PCB technology and minimization.

In addition, the designers no longer designed the PCB for a single purpose and use, they began working with Design for Test (DFT) strategies, which means that they always have to bear in mind the possibility of future fixes and changes and consider all the edge cases.

AGE OF MULTIPLICITY

In the new millennium the name of the game is – going hybrid. There is no longer the need to design many different devices to do just one thing, today every electronic device can perform many different actions. The phone is no longer used only for making calls and the TVs are getting smarter and smarter. Meanwhile the PCBs are well-designed for this technological revolution, so where will it go next?

SO WHERE IS IT GOING?

Only the future can tell if the growing trends we see in the PCB industry today will become the next big thing in the electronics industry, or maybe we will see the industry going in other directions:

- Flexible PCBs – The PCB industry is a fast-growing industry and the fastest-growing division of the PCB industry in recent years is flexible PCBs. Wearable electronics, flexible displays and medical applications are just some of the industries causing this growing demand for flexible and flex-rigid PCBs. As the technological abilities of flex (and stretchable) PCBs gets more sophisticated, the product design opportunities also increase and we are yet to realise the potential of this division of PCB industry in the coming years.

- High Power Boards – There is a significant thrust towards higher power PCBs (48V and higher), driven especially by the fast-growing solar energy and electric vehicles (EVs) industries. These high power boards require PCBs to mount larger components like battery packs while being able to deal with interference issues effectively.

- 3D printing technology – 3D printing has already become a reality in many industries and R&D departments, however when looking at printing a mixture of conductive and non-conductive materials, with the complexity and fragility of modern boards, there are still great challenges for this industry before it reaches the current abilities of the conventional PCB industry. Making the 3D printing of PCBs cost-effective is another huge challenge to overcome, especially for mass production.